- Services

- PROCESS MODELLING

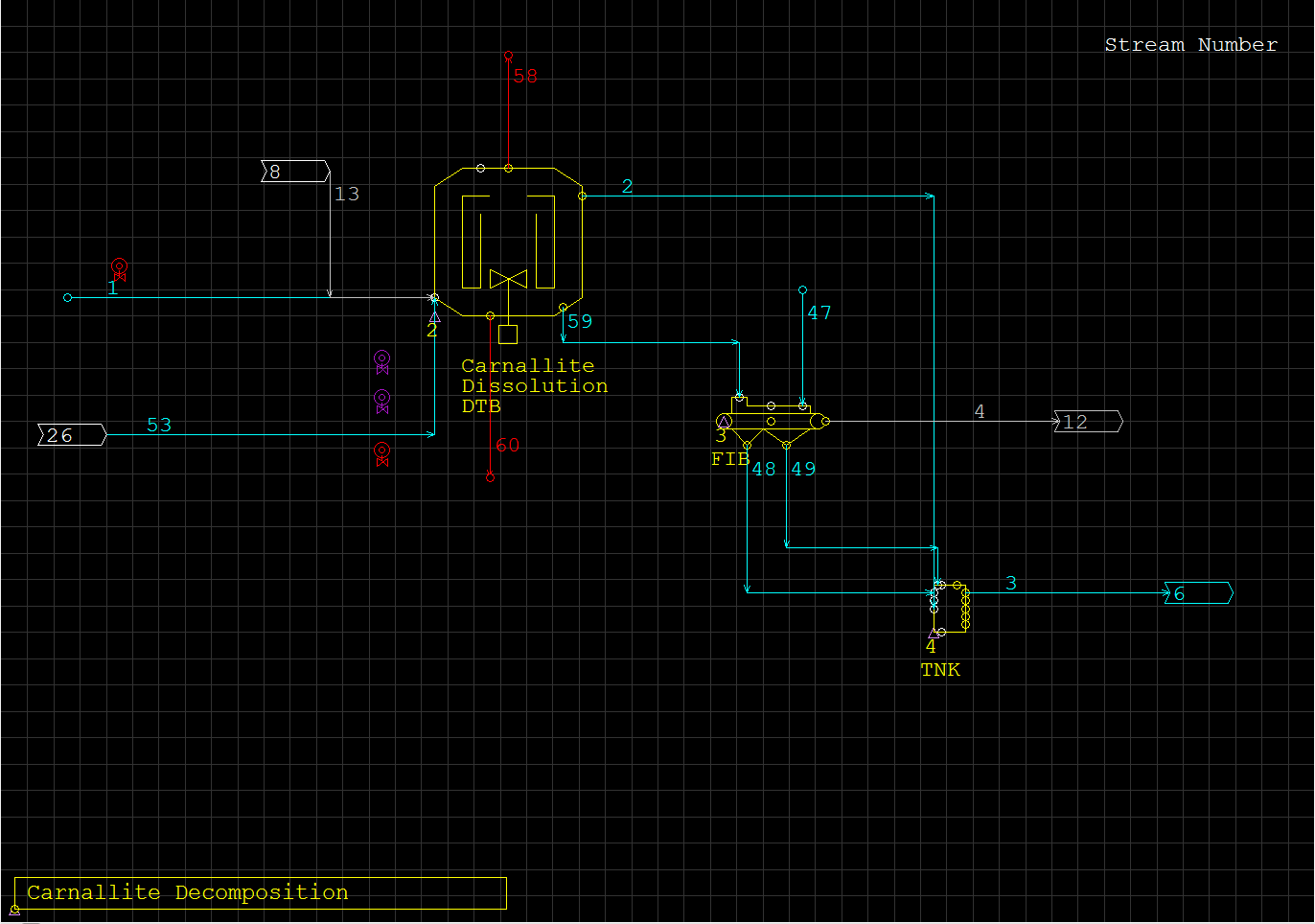

Sedgman Novopro’s general approach to Mineral Processing design involves two primary components typically carried out in parallel, namely, process test work and process modelling. A preliminary process model of the main unit operations (wet and dry) and inter-connecting circuits is generated to be used as a basis of the test work program. The results from the test work program are used to update, optimize and validate the unit operations in process model and the associated flowsheets.

It is our modelling capabilities that allows the engineers to extrapolate the necessary data from testwork to identify sensitivities to the process, as well as weak points within the design. Such analysis enables continuous feedback loop between modelling and testwork until the true picture is revealed.

In addition, the process modelling capacity allows for an adaptable process design, which can input new data as it is modified. This modelling allows for the development of transient start-up scenarios, ramp-up, and steady-state operations, providing process data outputs through the various scenarios, allowing for value engineering and cost-benefit decisions to be made.

Our core know-how is the development of processes utilizing commercial software such as METSIM™, PHREEQc™ in conjunction with proprietary modelling and testing techniques. The data and information obtained through the modelling activities serves as the main parameters required for the process design and provides insight on crucial aspects that may impact process recovery and economics.

Our METSIM™ models are built from a wealth of data from industry experts, and results from test work and piloting.

The reliability and accuracy of the Sedgman Novopro models have been compared and validated with data from both pilot plants and operating facilities.

Finally, when you work with us to design and optimize your processes, you can enable your project to meet sustainability goals. A well-designed process can result in a reduction in water and energy usage, less waste production and handling, and less greenhouse gas emissions.